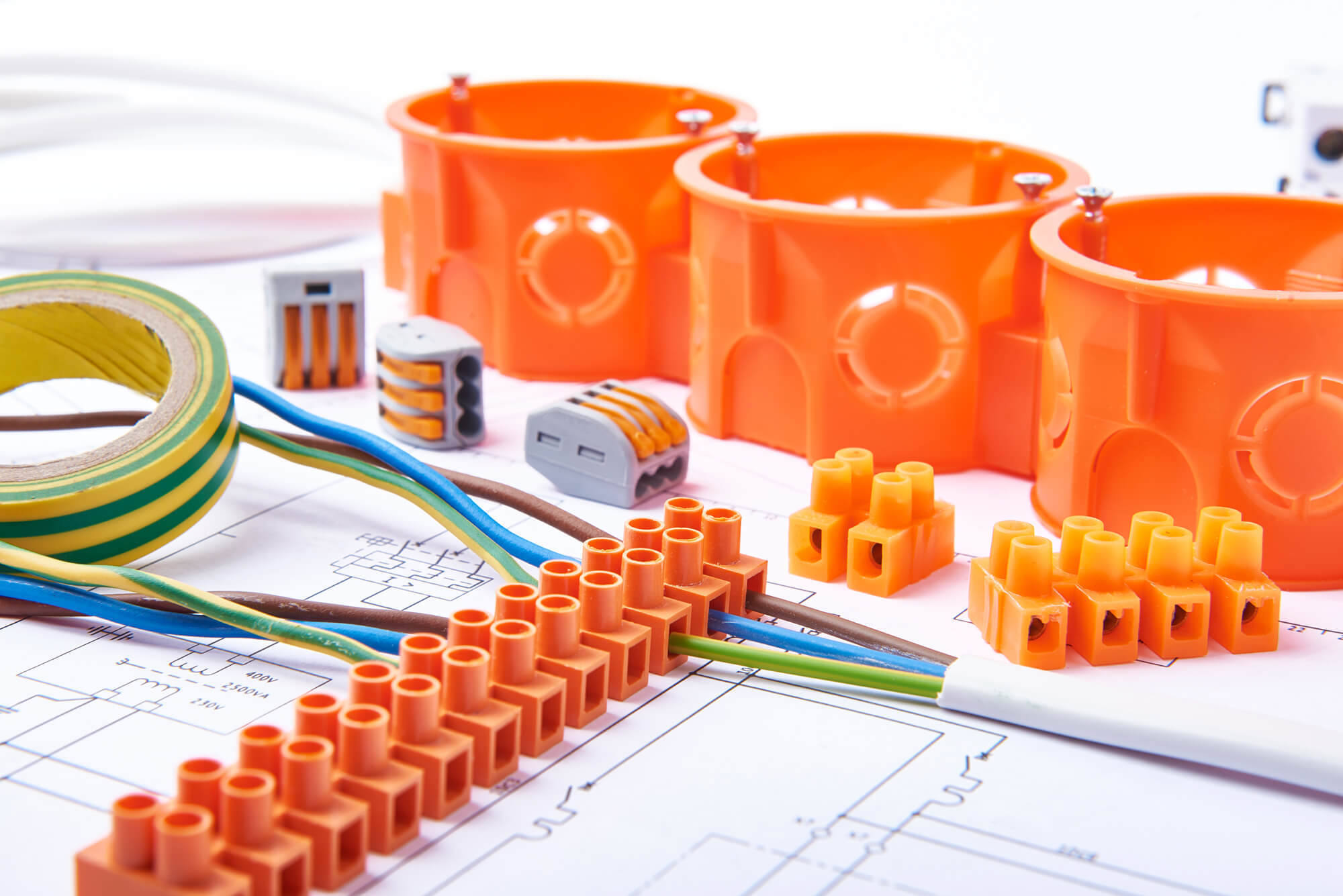

Electronic & Electrical

Manufacturers in the electrical and electronic industries face constant pressure to deliver components that are safe, reliable and cost‑effective. At Talisman Group, we support that challenge with more than 85 years of injection and compression moulding expertise.

Our UK‑based facilities produce precision thermoset and thermoplastic components that meet the demanding standards of modern electronics. From small insulating bushes to complex circuit breaker housings, every part is engineered for accuracy, durability and compliance. Our advanced moulding technology and sector‑specific knowledge will help you bring your products to market faster and with greater confidence.

Our electronic & electrical moulding capabilities

Our presses span a wide range of capacities, meaning we can support both small precision parts and larger mouldings. Whatever your specification, you’ll get consistent quality and dependable delivery. Our electronic and electrical moulding solutions include:

Thermoset moulding

Thermoset materials are ideal for components that must withstand high temperatures and electrical stress. We manufacture durable insulators, housings and switchgear parts that retain their shape and performance under demanding conditions.

Thermoplastic moulding

For applications that require lightweight, recyclable or visually finished parts, thermoplastics offer flexibility. We produce plugs, sockets, push button equipment and other components where precision and repeatability are critical.

Why choose Talisman Group?

Choosing the right electronic and electrical moulding partner can reduce risk, improve efficiency and strengthen your supply chain. Our goal is to make moulding a seamless part of your production strategy, so you can focus on innovation and growth. When you work with us, you benefit from:

- Compliance: Materials and processes aligned with strict electrical safety standards.

- Efficiency: UK‑based production that shortens your lead and shipping times.

- Flexibility: Capability to produce both small intricate parts and larger, complex mouldings.

- Reliability: Consistent quality across high‑volume production runs.

- Support: Unrivalled technical expertise, from design through to delivery.

Industries and applications we support

Electronic and electrical mouldings play a vital role across multiple sectors. We supply:

- Consumer electronics: Durable housings and connectors for everyday devices.

- Industrial controls: Switchgear, selector switches and protective housings designed for reliability.

- Power distribution: Insulating bushes and circuit breaker mouldings that meet strict safety standards.

- Transport electrics: Components for automotive and rail applications, where performance and compliance are critical.

With decades of experience, we can adapt our processes to meet your high‑volume requirements or specialist projects. Whatever your application, we can create components that perform consistently in the field.

Frequently asked questions

What types of electronic components can you mould?

We produce a broad range of parts for the electronics sector, including plugs, sockets, insulating bushes, switchgear components and circuit breaker housings. Each is manufactured to tight tolerances so you can depend on consistent fit and performance.

Do you offer both thermoset and thermoplastic moulding?

Yes. Thermosets are chosen for their strength, rigidity and heat resistance, making them ideal for safety‑critical applications. Thermoplastics, on the other hand, are lightweight, versatile and recyclable. Our team will guide you through the options, balancing performance, cost and sustainability so you get the right material for your project.

Can you handle both small and large components?

Absolutely. Our press range covers everything from tiny precision parts weighing just a few grams to large mouldings over one square metre. This flexibility means you don’t need multiple suppliers as your requirements evolve.

Do you supply internationally?

Yes. While our production is proudly UK‑based, we regularly ship components to clients across Europe, North America and further afield. International customers benefit from the same responsive support and reliable delivery as our UK partners.

How do you maintain quality and compliance?

Quality is built into every stage of our process. We use programmable controllers to maintain precise moulding conditions. Every batch undergoes rigorous testing to confirm compliance with electrical safety standards. Combined with decades of technical expertise, this ensures your components perform exactly as intended, project after project.

Can you support low‑volume or prototype runs?

Yes. While moulding is often associated with high‑volume production, we also support smaller runs and prototypes. This is particularly valuable if you’re trialling a new design, need samples for testing, or want to validate a component before scaling up to full production.

Let’s talk

If you’re looking for a trusted UK partner in electronic component moulding, Talisman Group is here to help. Our expertise in injection and compression moulding, combined with decades of sector experience, means you can expect components that meet the highest standards of safety and performance. Get in touch today to discuss your project and receive a tailored quote. Together, we’ll deliver the precision‑moulded parts your business depends on.